Our products come from crops located in areas close to the factory, in order to be able to supply ourselves with a high quality raw material, allowing us to handle and package the product the same day it is collected.

The production process begins after receiving the raw material. Once received in the factory, it is analyzed to verify that it meets the established quality standards, and a coding is assigned to it, which allows us to follow the tracking of our product throughout the production / marketing / consumption chain (Traceability).

Subsequently, it is washed to remove remains of earth, stones or other contaminants that the product may contain, and it is blanched in order to inactivate enzymes, prevent oxidation and facilitate subsequent peeling.

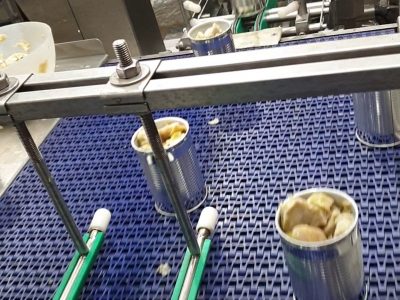

After peeling and going through the selection belts, the containers are filled. During filling, it is controlled, by means of automatic weighing, that the weight according to regulations is met.

Once the product is inside the containers, they are filled with the heated control liquid. The air contained in the container is then eliminated using jets of steam and they close automatically.

The containers go to the pasteurization tunnel, are dried and palletized for later storage and labeling.